No problem. That's how things work. If you import separate models on top of each they will "interfere" with each other. If you move those separate imported obj files away from each other all will be at the same level.

I have found a problem with importing OBJs.

- adze_cnc

- Vectric Wizard

- Posts: 4367

- Joined: Sat Jul 27, 2013 10:08 pm

- Model of CNC Machine: AXYZ 4008

- Location: Vancouver, BC, Canada

Re: I have found a problem with importing OBJs.

Re: I have found a problem with importing OBJs.

So no matter what the transform location is they import overlapping even though the separate objs all have their own position?

The pieces interlock so I am not a liberty to move them by hand. The cad setup has them positioned correctly and Aspire import ignores this?

Looks like each import aligns with the project center.

I originally had this as one OBJ put went back into the cad system to split the objects to toolpaths and now they land in Aspire not by their own transforms?

I am about to blow a gasket over this.

The pieces interlock so I am not a liberty to move them by hand. The cad setup has them positioned correctly and Aspire import ignores this?

Looks like each import aligns with the project center.

I originally had this as one OBJ put went back into the cad system to split the objects to toolpaths and now they land in Aspire not by their own transforms?

I am about to blow a gasket over this.

Re: I have found a problem with importing OBJs.

The question remains then how does one get 3 toolpaths on to a imported model? I can not draw the vectors by hand as this would degrade the specificity of the design.

- adze_cnc

- Vectric Wizard

- Posts: 4367

- Joined: Sat Jul 27, 2013 10:08 pm

- Model of CNC Machine: AXYZ 4008

- Location: Vancouver, BC, Canada

Re: I have found a problem with importing OBJs.

If all the objects are in place in Unity I fail to understand why you are bothering to export them to separate OBJ files. Why export all as a composite OBJ file?

Your terminology of “toolpaths” is confusing. Aspire creates toolpaths from various 3D models and 2D geometry which it calls “vectors”. Adobe Illustrator calls them “paths” and Rhinoceros 3D calls them “curves”.

Attached are some sample files (the DWG and OBJ files are compressed to ZIP files for the forum software’s benefit):

Your terminology of “toolpaths” is confusing. Aspire creates toolpaths from various 3D models and 2D geometry which it calls “vectors”. Adobe Illustrator calls them “paths” and Rhinoceros 3D calls them “curves”.

Attached are some sample files (the DWG and OBJ files are compressed to ZIP files for the forum software’s benefit):

- curves.dwg : the profiles of 3 objects

- composite.obj : the 3 objects in one obj file

- 3 models in one.crv : curves and objects imported into VCarve v9.519

- Attachments

-

- 3 models in one.crv

- (33.5 KiB) Downloaded 18 times

-

- curves.dwg.zip

- (5.54 KiB) Downloaded 17 times

-

- composite.obj.zip

- (10.72 KiB) Downloaded 16 times

- martin54

- Vectric Archimage

- Posts: 7349

- Joined: Fri Nov 09, 2012 2:12 pm

- Model of CNC Machine: Gerber 48, Triac PC, Isel fixed gantry

- Location: Kirkcaldy, Scotland

Re: I have found a problem with importing OBJs.

Can you post the CRV3D file, copyright permitting & the OJB file, I haven't imported a large number of 3rd party 3D model files but haven't had any problems with those that I have. Have you tried other formats such as STL?

If you can't post for some reason then consider sending it to Vectric support

support@vectric.com

Hard to tell from the screenshots but this looks like a job that would be better suited to 2D toolpaths rather than 3D

If you can't post for some reason then consider sending it to Vectric support

support@vectric.com

Hard to tell from the screenshots but this looks like a job that would be better suited to 2D toolpaths rather than 3D

Re: I have found a problem with importing OBJs.

I have this as one composite obj but the vectorization wouldnt let me create separate toolpaths.adze_cnc wrote: ↑Sun Apr 02, 2023 6:12 amIf all the objects are in place in Unity I fail to understand why you are bothering to export them to separate OBJ files. Why export all as a composite OBJ file?

Your terminology of “toolpaths” is confusing. Aspire creates toolpaths from various 3D models and 2D geometry which it calls “vectors”. Adobe Illustrator calls them “paths” and Rhinoceros 3D calls them “curves”.

Attached are some sample files (the DWG and OBJ files are compressed to ZIP files for the forum software’s benefit):

The curves and objects were exported from Rhinoceros 3D.

- curves.dwg : the profiles of 3 objects

- composite.obj : the 3 objects in one obj file

- 3 models in one.crv : curves and objects imported into VCarve v9.519

There are four toolpaths to the project, in order:

Contour for the slope,

1-1/4" hole for the washer pocket,

1/4" hole for the shafts and a profile for bridging and final cutout.

I will recreate the composite obj and reimport to address this spot in the thread.

- Adrian

- Vectric Archimage

- Posts: 14653

- Joined: Thu Nov 23, 2006 2:19 pm

- Model of CNC Machine: ShopBot PRS Alpha 96x48

- Location: Surrey, UK

Re: I have found a problem with importing OBJs.

This and other posts you have made have me thinking that maybe you're missing something with creating 3D toolpaths in Aspire.

Can you explain your workflow as I can't understand what it is you're trying to do and where "vectorization" comes into it.

The file you posted on your other thread which looks the same as this one would be far more efficiently machined as 2D toolpaths with a fluting or chamfered toolpath for the angle or you could use a moulding toolpath.

Re: I have found a problem with importing OBJs.

The washer holes end up in the contour toolpath so they are cut with a ball end. The bottoms are round and this incorrect.

I need somehow to cut by levels of the same component.

I am trying to manage the handy work in Aspire to a low level of effort and trying to rely on the computer working in cad.

Why the objs come in at some strange center position is a bug.

If this is true then Aspire is missing one great property that could propel it into cutting cad files instead of getting into the product with 'hands on' where it should not be so.

The current workflow now is trying to 'make' aspire conform, trying to get community support to solve this problem in Aspire using handy work, this might solve the problem but for other incoming objs this is not the way to work due to making repeatability a hands on function instead of the computer doing something correctly,

and I could put registration points in the model to hand align the multiple objs. Arent computers supposed to work for us? And once again I have to go hands on in a area that the computer should do the work correctly.

The big elephant in the room is why do all other software platforms import files correctly on point? Am I assuming something here about Aspire? Do I need to file a report? How do others do it with out getting into manual labor? For the price of this package it should. If I were to mention this on other package forums I would get the deer in the headlights look as this is simply not any thing to call a failure or even be talking about. I dont want to 'play manually' in Aspire by moving things around to placate a package failure.

I always push products to their limits as I know what I want to get done and lo and behold the package doesnt work that way. And its not that I dont know what I am doing.

If others are importing multiple objs and 'NOT' manually manipulating then I would like to here from them as to how they perform this task.

I can not believe I have spent days on this trivial function failure. In the other packages one simply clicks the import and moves on with their intended workflow with no hiccups or manual munging.

I need somehow to cut by levels of the same component.

I am trying to manage the handy work in Aspire to a low level of effort and trying to rely on the computer working in cad.

Why the objs come in at some strange center position is a bug.

If this is true then Aspire is missing one great property that could propel it into cutting cad files instead of getting into the product with 'hands on' where it should not be so.

The current workflow now is trying to 'make' aspire conform, trying to get community support to solve this problem in Aspire using handy work, this might solve the problem but for other incoming objs this is not the way to work due to making repeatability a hands on function instead of the computer doing something correctly,

and I could put registration points in the model to hand align the multiple objs. Arent computers supposed to work for us? And once again I have to go hands on in a area that the computer should do the work correctly.

The big elephant in the room is why do all other software platforms import files correctly on point? Am I assuming something here about Aspire? Do I need to file a report? How do others do it with out getting into manual labor? For the price of this package it should. If I were to mention this on other package forums I would get the deer in the headlights look as this is simply not any thing to call a failure or even be talking about. I dont want to 'play manually' in Aspire by moving things around to placate a package failure.

I always push products to their limits as I know what I want to get done and lo and behold the package doesnt work that way. And its not that I dont know what I am doing.

If others are importing multiple objs and 'NOT' manually manipulating then I would like to here from them as to how they perform this task.

I can not believe I have spent days on this trivial function failure. In the other packages one simply clicks the import and moves on with their intended workflow with no hiccups or manual munging.

Re: I have found a problem with importing OBJs.

https://drive.google.com/file/d/1cooou7 ... share_linkmartin54 wrote: ↑Sun Apr 02, 2023 12:20 pmCan you post the CRV3D file, copyright permitting & the OJB file, I haven't imported a large number of 3rd party 3D model files but haven't had any problems with those that I have. Have you tried other formats such as STL?

If you can't post for some reason then consider sending it to Vectric support

support@vectric.com

Hard to tell from the screenshots but this looks like a job that would be better suited to 2D toolpaths rather than 3D

https://drive.google.com/file/d/1B_kIoS ... share_link

https://drive.google.com/file/d/1tW3oVq ... share_link

These are the 3 imports all based on the same center point. Import them in any other package and they line up correctly.

Should be available for anyone with with links.

- adze_cnc

- Vectric Wizard

- Posts: 4367

- Joined: Sat Jul 27, 2013 10:08 pm

- Model of CNC Machine: AXYZ 4008

- Location: Vancouver, BC, Canada

Re: I have found a problem with importing OBJs.

importing an OBJ file at some strange position (and I expect that it isn’t strange but I’ve not invested time in finding the logic) is only a bug if the import was meant to import them at a specific location. For now it is an annoyance (to you) or an oversight or any other categorization. support@vectric.com is the place to send a feature request—in this case “honour the X,Y co-ordinate of the OBJ or STL or 3DM file on import”. Let bugs relate to things that are supposed to happen but don’t.paulmoore wrote: ↑Sun Apr 02, 2023 7:42 pmWhy the objs come in at some strange center position is a bug.

[blah blah]

The big elephant in the room is why do all other software platforms import files correctly on point? Am I assuming something here about Aspire?

[things that need more time and effort to parse than I’m wiliing to endure]

VCarve (Aspire, Cut3D) does import things correctly as “all other software platforms do"—as long as you give it correct things to import. If you only give it a 3D model in the form of an OBJ file how are profile toolpaths, pocket toolpaths and the like to get the information they need? You’ll have to provide that either be exporting 2D curves/geometry from your source program or by manually creating it in Aspire.

If the Vectric programs could import OBJ files that are saved as NURBS objects then Aspire and its sibling software could automatically extract edges for features within the 3D model—such as drill holes and counterbores. Perhaps that’s another feature request to send to: support@vectric.com ?

I import 3D jobs at least weekly and have been doing so for the past 10 years or so. Any “vectorization” is done in the 3D modelling software and brought into VCarve as in the samples posted above. I can’t remember the last time I “vectorized” any 3D projects from within VCarve. Perhaps all those “other software platforms” are ones that should be used? Why VCarve? The price was right as I didn’t need the modelling aspects of Aspire. VCarve does all that Aspire does except for 3D modelling (3D modelling that doesn’t involve clipart compositing that is).

- mtylerfl

- Vectric Archimage

- Posts: 5892

- Joined: Thu Jan 29, 2009 3:54 am

- Model of CNC Machine: -CarveWright CNC -ShopBot Buddy PRSAlpha

- Location: Brunswick, GA

Re: I have found a problem with importing OBJs.

You can import your single OBJ, so everything is positioned as it was created.

Then, use the “Split the selected component using a vector” tool to separate the OBJ into pieces, as you wish.

Refer to the software manual for usage instructions. I think there is a video tutorial, too.

Then, use the “Split the selected component using a vector” tool to separate the OBJ into pieces, as you wish.

Refer to the software manual for usage instructions. I think there is a video tutorial, too.

Michael Tyler

facebook.com/carvebuddy

-CarveWright CNC

-ShopBot Buddy PRSAlpha CNC

facebook.com/carvebuddy

-CarveWright CNC

-ShopBot Buddy PRSAlpha CNC

Re: I have found a problem with importing OBJs.

This creates extra layering that shows up on the sloped edges. The operation of the final device does not allow this. All of the 12 layers must be of the same height.mtylerfl wrote: ↑Sun Apr 02, 2023 11:39 pmYou can import your single OBJ, so everything is positioned as it was created.

Then, use the “Split the selected component using a vector” tool to separate the OBJ into pieces, as you wish.

Refer to the software manual for usage instructions. I think there is a video tutorial, too.

I have 3 models to import. There are 4 toolpaths. In order is:

The washer layer for the large hole cut which 5mm deep, material #1.

The Ring layer for the 1/4" shaft holes which are the 25.25mm deep full depth of the material, material #2.

The Rim layer for the slope using the 3d rough and 3d finish, Material #3.

The Ring plus the Rim layers for a profile cut with bridges on the inner arc, material #4.

These 3 pieces are coming from a cad model and can not be altered in their positions in any way. I have made the effort to keep these in the same project but the different size pieces are all adjusted by Aspire to fit its virtual center. The product is altering my data. I consider this a bug and it has been reported to the support@vectric.com process I received 2 replies and replied back with further analysis. Now I wait 2 days and possibly over the weekend for Vectric to formulate a response or patch.

The overlap which is apparent shows each piece as internal overlap and the full pieces are overlapped.

This all begs the question will that overlap be part of the model on the router table or is it just a display problem?

This will be another step of useless trial and error when the models should be imported based upon my data.

Do I go through the motion to import each model I want a toolpath for into separate projects and then see if each piece lines up correctly on the sheet on the physical table?

The datum is modifiable so why not the incoming model? Or am I missing something. I have tried a lot of switch and data combinations in Aspire. I could have missed one but there is not a lot to this. I import my models to Blender as a test and they just work without any manipulations.

See where I am going with this?

The Vectric import decides where the models should be placed instead of what my specifications demand.

In the support ticket I have specified that this product is the only one that breaks user data with importing. I mention this in other graphics forums and get the deer in headlights or 'Wait. What? The import breaks your data? 'Why?'

I dont know.

If Vectric Aspire allows multiple imports then why not do it correctly or present a user setting to allow or disallow?

Hopefully I have supplied enough information for a reasonable answer.

Once again slice or dice or manual manipulations are not permissible regardless of the software's ability. I dont have to do this in other packages.

-

ZipperHead55

- Vectric Craftsman

- Posts: 188

- Joined: Fri Apr 04, 2014 2:21 am

- Model of CNC Machine: Axiom AR4Pro+ and AR8Pro+

- Location: Edmonton, Alberta, Canada

Re: I have found a problem with importing OBJs.

I downloaded the 3 files, and unless I'm out to lunch, these models are huge.

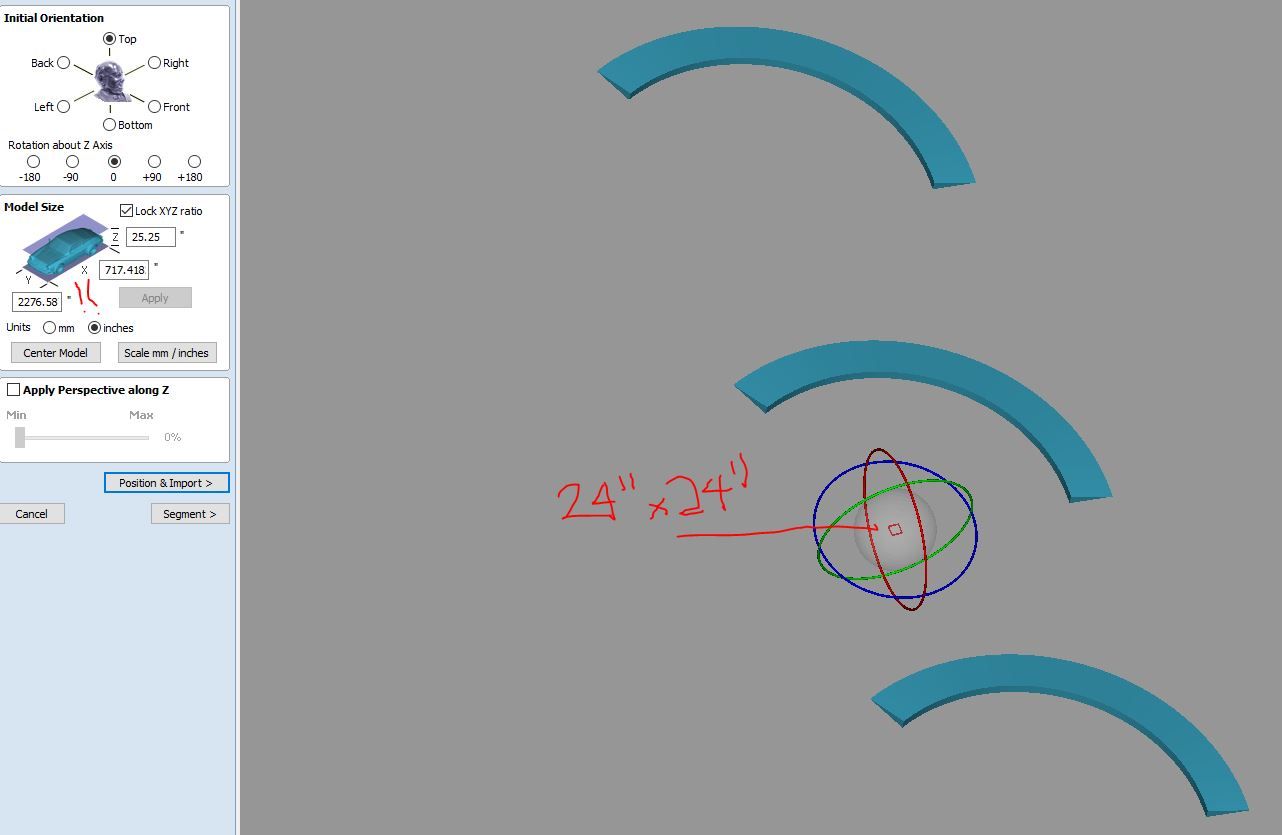

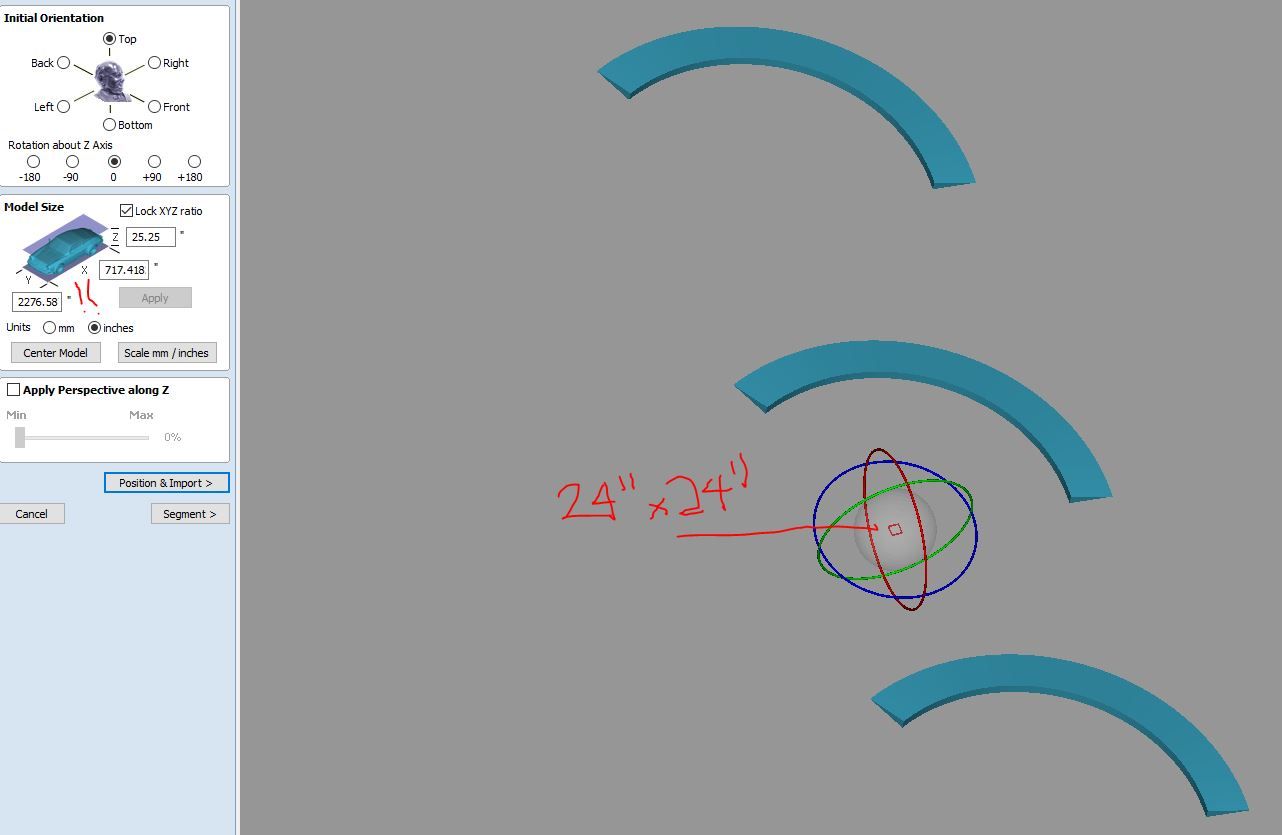

Look at the image here:

The size indicates 2276 inches (or ~190 feet). Switch it to mm, and it's still 2.27m, which is 90 inches.

Each of the files has the same (oversized) proportions, so I would argue that rather than being a software "bug", it is a case of GIGO (garbage in, garbage out), and I can't see how this is Vectric's "fault". I'm not sure how you got all 3 to fit into your work area (unless you have the world's largest CNC router (particularly if it's in inches (190 feet).

Maybe I'm missing something simple here, but it appears that you modeled (or exported) with the wrong settings.

Allan

PS I am using Aspire 11.504

Look at the image here:

The size indicates 2276 inches (or ~190 feet). Switch it to mm, and it's still 2.27m, which is 90 inches.

Each of the files has the same (oversized) proportions, so I would argue that rather than being a software "bug", it is a case of GIGO (garbage in, garbage out), and I can't see how this is Vectric's "fault". I'm not sure how you got all 3 to fit into your work area (unless you have the world's largest CNC router (particularly if it's in inches (190 feet).

Maybe I'm missing something simple here, but it appears that you modeled (or exported) with the wrong settings.

Allan

PS I am using Aspire 11.504

Re: I have found a problem with importing OBJs.

Switch to mm on the import. The material is 25.25mm which is ~1". Otherwise one can not simply purchase a material 25" thick without the other X and Z being ginormous. The flatbed truck wouldnt even fit down my street,ZipperHead55 wrote: ↑Sun Apr 09, 2023 1:40 amI downloaded the 3 files, and unless I'm out to lunch, these models are huge.

Look at the image here:

The size indicates 2276 inches (or ~190 feet). Switch it to mm, and it's still 2.27m, which is 90 inches.

Each of the files has the same (oversized) proportions, so I would argue that rather than being a software "bug", it is a case of GIGO (garbage in, garbage out), and I can't see how this is Vectric's "fault". I'm not sure how you got all 3 to fit into your work area (unless you have the world's largest CNC router (particularly if it's in inches (190 feet).

Maybe I'm missing something simple here, but it appears that you modeled (or exported) with the wrong settings.

Allan

PS I am using Aspire 11.504

-

ZipperHead55

- Vectric Craftsman

- Posts: 188

- Joined: Fri Apr 04, 2014 2:21 am

- Model of CNC Machine: Axiom AR4Pro+ and AR8Pro+

- Location: Edmonton, Alberta, Canada

Re: I have found a problem with importing OBJs.

There are a few things that I don't understand about your "problem".

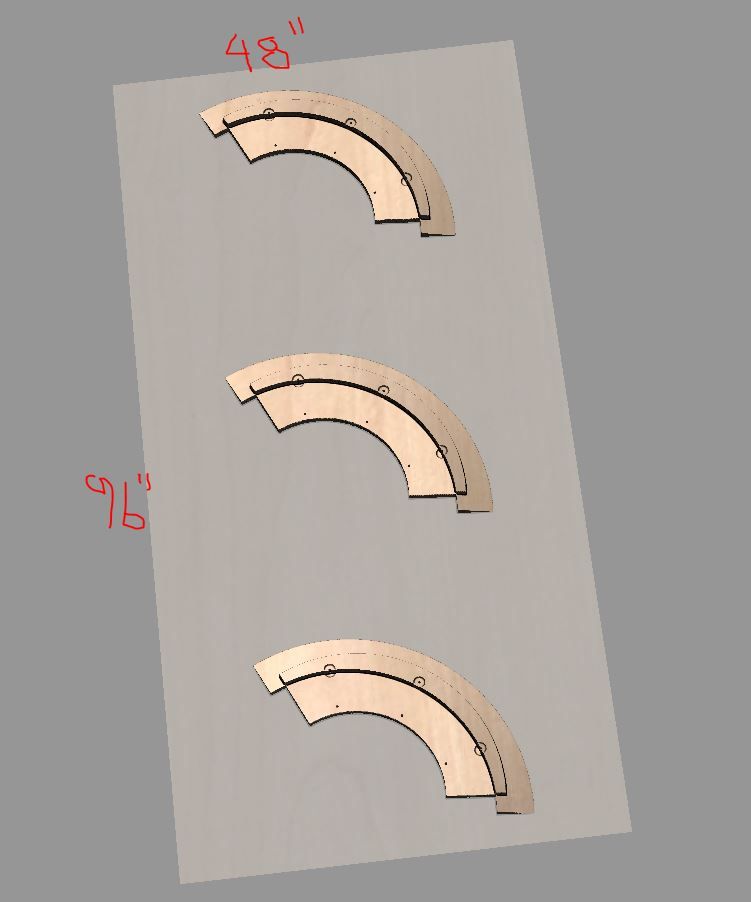

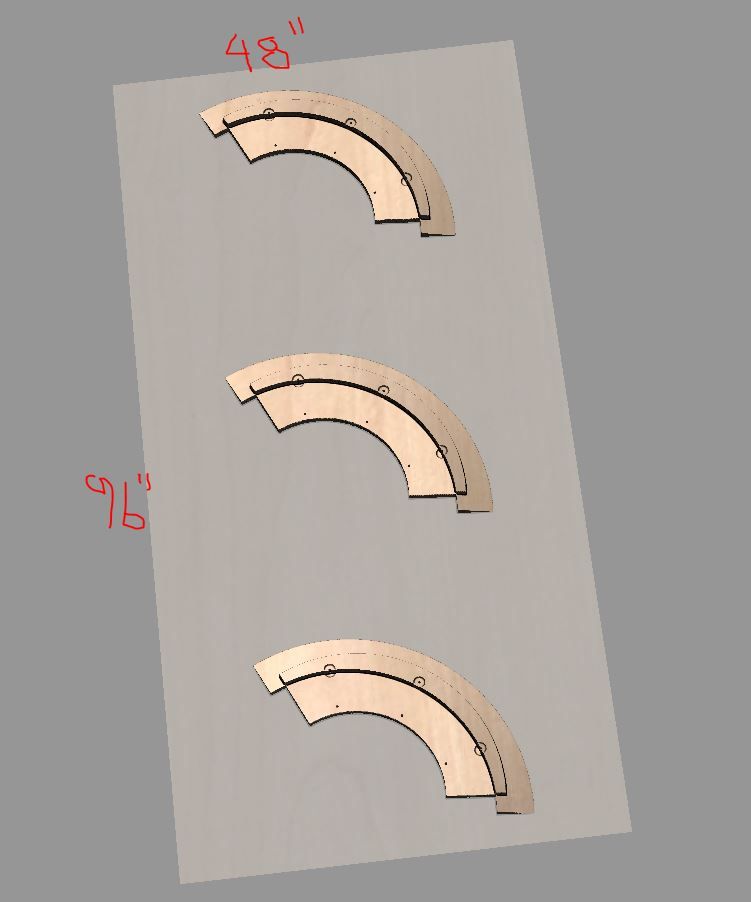

1) Why are there 3 objects within each model? Taking a cursory look at them, it appears that they are the same model, duplicated. And if there is a reason, why are they so far apart? How big is the bed of your CNC?

2) How did you get them to import in the manner (stacked on top of each other) that you posted an image of? The only way I could achieve anything close to that was to import them (after selecting "Scale mm/inches" in the Model Size tab), and then they imported like the following image:

I guess, the simple solution, would be to import one single component at a time (instead of 3 that are spread out far apart for no reason I can think of), selecting "Center Model" (which would center each model in the center of the workspace, using the origin of each model). And then, once you have created toolpaths for those models, do an array (or alternative method) to duplicate it as many times as you need.

I think that the files that you included links for AREN'T the same files as you provided pictures of in your initial posts, because I imported the files into Aspire, 3DS Max and Blender, and they ALL have the components spread out, and some of the components look different from the results that I have achieved.

As an aside, why are you creating the files in Unity, if you have Aspire? It seems like a lot of work to create them in the one platform (Unity), which I only have a passing familiarity with, and I didn't recall thinking it was appropriate as a CAD platform, but you do you, yeah?!) and then import them into Aspire. Aspire is more than capable of creating those models, and you wouldn't have to hop in/out of different software platforms for no real gain that I can see.

It seems that you are more intent on complaining about a problem that doesn't really exist (if you were to use a more sensible workflow), and trying to humble-brag about your proficiency about your mad skillz in other software apps. We had a saying in the army about people who are book smart, but lacking common sense: "They can tell you the square root of a jar of pickles, but they don't know how to open it".

Allan

1) Why are there 3 objects within each model? Taking a cursory look at them, it appears that they are the same model, duplicated. And if there is a reason, why are they so far apart? How big is the bed of your CNC?

2) How did you get them to import in the manner (stacked on top of each other) that you posted an image of? The only way I could achieve anything close to that was to import them (after selecting "Scale mm/inches" in the Model Size tab), and then they imported like the following image:

I guess, the simple solution, would be to import one single component at a time (instead of 3 that are spread out far apart for no reason I can think of), selecting "Center Model" (which would center each model in the center of the workspace, using the origin of each model). And then, once you have created toolpaths for those models, do an array (or alternative method) to duplicate it as many times as you need.

I think that the files that you included links for AREN'T the same files as you provided pictures of in your initial posts, because I imported the files into Aspire, 3DS Max and Blender, and they ALL have the components spread out, and some of the components look different from the results that I have achieved.

As an aside, why are you creating the files in Unity, if you have Aspire? It seems like a lot of work to create them in the one platform (Unity), which I only have a passing familiarity with, and I didn't recall thinking it was appropriate as a CAD platform, but you do you, yeah?!) and then import them into Aspire. Aspire is more than capable of creating those models, and you wouldn't have to hop in/out of different software platforms for no real gain that I can see.

It seems that you are more intent on complaining about a problem that doesn't really exist (if you were to use a more sensible workflow), and trying to humble-brag about your proficiency about your mad skillz in other software apps. We had a saying in the army about people who are book smart, but lacking common sense: "They can tell you the square root of a jar of pickles, but they don't know how to open it".

Allan