stepover percent during final finish

-

auga

- Vectric Apprentice

- Posts: 61

- Joined: Thu Jun 15, 2017 11:24 pm

- Model of CNC Machine: TinyG - Homemade

stepover percent during final finish

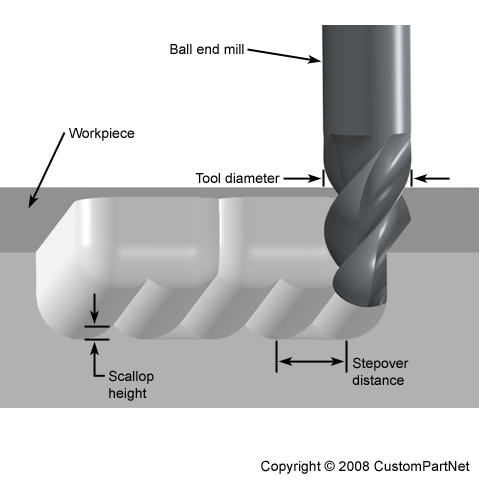

So I watching videos on cutting models and I am still confused on editing the ball nose bit to 8 - 12% But another

video says 14%.

So if I understand that this is the distance that the ball nose cross over the path when cutting the 2.5d model in order

to keep the finish smooth but having the x% cross over.

Do I understand that correctly?

video says 14%.

So if I understand that this is the distance that the ball nose cross over the path when cutting the 2.5d model in order

to keep the finish smooth but having the x% cross over.

Do I understand that correctly?

- Rcnewcomb

- Vectric Archimage

- Posts: 5919

- Joined: Fri Nov 04, 2005 5:54 am

- Model of CNC Machine: 24x36 GCnC/WinCNC with ATC

- Location: San Jose, California, USA

- Contact:

Re: stepover percent during final finish

Yes.So if I understand that this is the distance that the ball nose cross over the path when cutting the 2.5d model in order

to keep the finish smooth but having the x% cross over.

If you have used a lawn mower you may recall that you have to overlap as you go back and forth so you ensure all the grass gets cut. Think of the stepover as what percent of the width do you move over for each pass.

The smaller the stepover the less likely you are to see ridges or lines in the final finish. However, a smaller stepover increases machining time.

- Randall Newcomb

10 fingers in, 10 fingers out, another good day in the shop

10 fingers in, 10 fingers out, another good day in the shop

- Leo

- Vectric Wizard

- Posts: 4091

- Joined: Sat Jul 14, 2007 3:02 am

- Model of CNC Machine: 1300 x 1300 x 254 Chinese Made

- Location: East Freetown, Ma.

- Contact:

Re: stepover percent during final finish

I am really anal sometimes but on finish passes where I want a fine finish, no ridges, and no sanding I will set my stepover as low as 3-5%

Roughing is a different story.

The picture Randal posted is a REALLY good example.

Roughing is a different story.

The picture Randal posted is a REALLY good example.

Imagine the Possibilities of a Creative mind, combined with the functionality of CNC

-

auga

- Vectric Apprentice

- Posts: 61

- Joined: Thu Jun 15, 2017 11:24 pm

- Model of CNC Machine: TinyG - Homemade

Re: stepover percent during final finish

Thanks guys. Its funny I was thinking of the lawn mowing example to explain this. Thank you for posting the graphic that really helped. So is 3 - 8% a good number to use? Or is there a rule

based on the size of the ball nose I use?

I finished 3 test small pieces and it really worked out on #2 and #3 as soon as I figured out the boundary offset settings.

Thanks again.

based on the size of the ball nose I use?

I finished 3 test small pieces and it really worked out on #2 and #3 as soon as I figured out the boundary offset settings.

Thanks again.

- Rcnewcomb

- Vectric Archimage

- Posts: 5919

- Joined: Fri Nov 04, 2005 5:54 am

- Model of CNC Machine: 24x36 GCnC/WinCNC with ATC

- Location: San Jose, California, USA

- Contact:

Re: stepover percent during final finish

I prefer 8%

YMMV

YMMV

- Randall Newcomb

10 fingers in, 10 fingers out, another good day in the shop

10 fingers in, 10 fingers out, another good day in the shop

- Xxray

- Vectric Wizard

- Posts: 2304

- Joined: Thu Feb 17, 2011 8:47 am

- Model of CNC Machine: CAMaster Stinger 1

- Location: MI USA

Re: stepover percent during final finish

I usually go with 14% using a .03125 bit ... Have tried 8% with no discernible difference to the eyeball.

Doug

- Leo

- Vectric Wizard

- Posts: 4091

- Joined: Sat Jul 14, 2007 3:02 am

- Model of CNC Machine: 1300 x 1300 x 254 Chinese Made

- Location: East Freetown, Ma.

- Contact:

Re: stepover percent during final finish

There is no rule of thumb here.

It's all a matter of personal preference and what the desired outcome is.

What is good to one person may not be good to another.

That does not mean anything is correct or incorrect.

It's just a matter of what makes you happy.

The stepover ridges could be laid out to see the ridges, but there will be ridges even if you cannot feel them.

The smaller the stepover the smaller the ridges.

At a 2% stepover the ridges are so small that they are almost not there.

Then it also depends on the diameter of the ball nosed end mill.

The larger the diameter, the flatter the nose of the end mill will be.

The smaller the ridges and the more forgiving the stepover is.

Another thing to consider is time. If a job is going to run for 4-5 hours and I am just putting around the house and yard and I can pop in to check on the machine - I don't care that it took a long time.

On the other side of the coin, if I have a 5% stepover and the finish is going to take 18 hours and I am not going to be watching it, I will adjust the parameters to get a reasonable cut time and compromise of the quality

Personally, I just hate a fixed rule of thumb.

I find it better to understand and adjust according to my needs or desires.

Like I said - I can be very very anal about this stuff.

I can tend to be a bit less practical.

It's all a matter of personal preference and what the desired outcome is.

What is good to one person may not be good to another.

That does not mean anything is correct or incorrect.

It's just a matter of what makes you happy.

The stepover ridges could be laid out to see the ridges, but there will be ridges even if you cannot feel them.

The smaller the stepover the smaller the ridges.

At a 2% stepover the ridges are so small that they are almost not there.

Then it also depends on the diameter of the ball nosed end mill.

The larger the diameter, the flatter the nose of the end mill will be.

The smaller the ridges and the more forgiving the stepover is.

Another thing to consider is time. If a job is going to run for 4-5 hours and I am just putting around the house and yard and I can pop in to check on the machine - I don't care that it took a long time.

On the other side of the coin, if I have a 5% stepover and the finish is going to take 18 hours and I am not going to be watching it, I will adjust the parameters to get a reasonable cut time and compromise of the quality

Personally, I just hate a fixed rule of thumb.

I find it better to understand and adjust according to my needs or desires.

Like I said - I can be very very anal about this stuff.

I can tend to be a bit less practical.

Imagine the Possibilities of a Creative mind, combined with the functionality of CNC

-

jerry carney

- Vectric Craftsman

- Posts: 122

- Joined: Fri Mar 03, 2017 6:16 pm

- Model of CNC Machine: shopbot desktop

- Location: Crete Il.

Re: stepover percent during final finish

Great description, very clear.

-

MarkJohnston

- Vectric Wizard

- Posts: 823

- Joined: Tue Jun 01, 2010 4:51 pm

- Model of CNC Machine: CAMaster MC4848

- Location: Prescott AZ

Re: stepover percent during final finish

Very good description Leo, I second that.

I will set the step over a little higher depending on the models detail. Sometimes its not that much difference for the time it takes.

I dremel tool with a proper sanding mop that's about 220 grit can makes some pretty fast sanding but you have to be careful not to sand out wanted detail.

Mark

I will set the step over a little higher depending on the models detail. Sometimes its not that much difference for the time it takes.

I dremel tool with a proper sanding mop that's about 220 grit can makes some pretty fast sanding but you have to be careful not to sand out wanted detail.

Mark

- Rcnewcomb

- Vectric Archimage

- Posts: 5919

- Joined: Fri Nov 04, 2005 5:54 am

- Model of CNC Machine: 24x36 GCnC/WinCNC with ATC

- Location: San Jose, California, USA

- Contact:

Re: stepover percent during final finish

I keep hoping Dremel will add an undo button to the tooldremel tool with a proper sanding mop that's about 220 grit can makes some pretty fast sanding but you have to be careful not to sand out wanted detail.

- Randall Newcomb

10 fingers in, 10 fingers out, another good day in the shop

10 fingers in, 10 fingers out, another good day in the shop

- sharkcutup

- Vectric Wizard

- Posts: 2925

- Joined: Sat Mar 26, 2016 3:48 pm

- Model of CNC Machine: Shark HD3 Pro Extended Bed with Spindle

- Location: U.S.A.

Re: stepover percent during final finish

Using a .09375 radius .1875 dia ballnose with 10% (.0188") step over this Moose Model came out rather well - little light sanding to no sanding is all that is needed!

Sharkcutup

Sharkcutup

V-Carve Pro Tips, Gadget Tips & Videos

YouTube Channel - Sharkcutup CNC

V-Carve Pro 12.004

YouTube Channel - Sharkcutup CNC

V-Carve Pro 12.004