Hi all,

I just recently got introduced into 3d router works,

what I do I design my mesh/objects in 3ds max and then export to vectric cut3d as 3ds files,

from cut 3d I generate 2 nc files for toolpath output.

I did a couple of test and they turned out great,

however recently I was doing a real job and had to do it 3 times over as I was getting undesirable results...

What happened is the first rough pass seems like its cutting 0.125" off its origin. my origin is set in the bottom left corner.

I set up the files -2 passes the 1st rough pass to shave the majority of material with 0.25" 4 flute center cut helical bit and the 2nd precision pass I use 0.25" ball nose bit, the material thickness is 1.5" its an embossed logo etc..,

What happens is it seems like either the first pass or the second pass is offsetting by 0.125" or more and I don't understand why...

to control and send the jobs to router table we use tool path software.

Does this ever happen to anyone else ?

any help would be appreciated.

thanks,

Drew

Cut3d undesirable results

Re: Cut3d undesirable results

Hey Guys,

still wondering if anyone can relate to my problem,

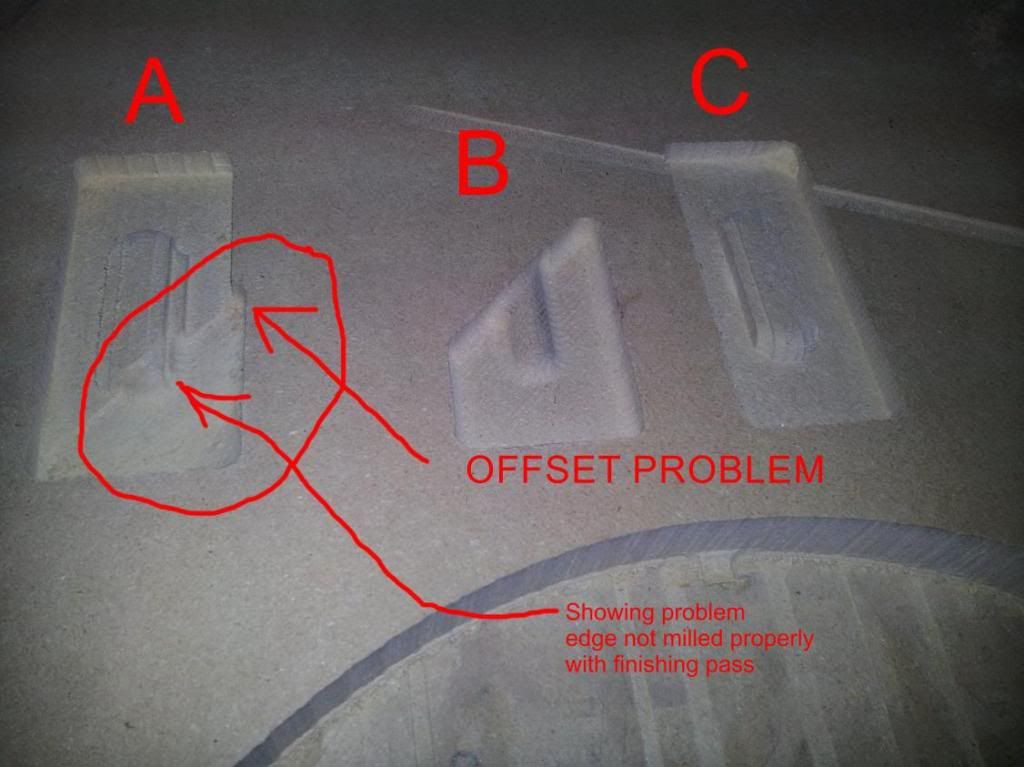

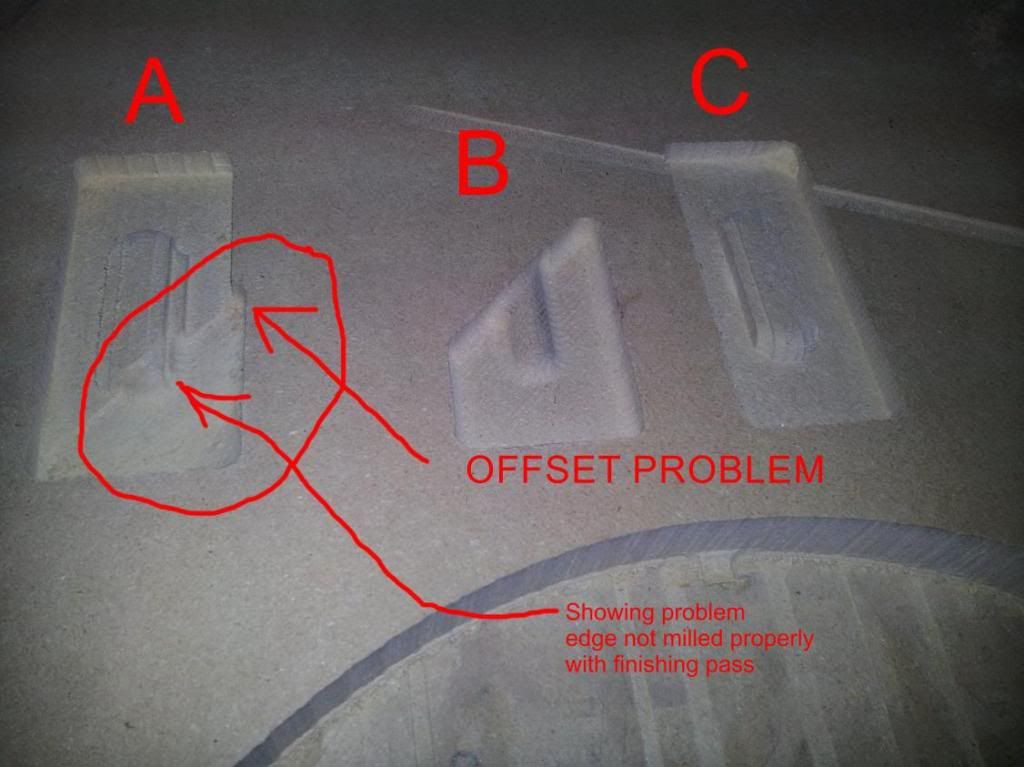

here is an image showing as what is happening,

I just ran some more tests and noticed that if I process the same job with the same ball nose bit it looks great..

example A - showing rough path and starting finishing path,

example B - showing finishing path only , we skipped the rough path, (great finish)

example C - showing finished rough path only.

any help would be greatly appreciated.

thanks,

Drew

still wondering if anyone can relate to my problem,

here is an image showing as what is happening,

I just ran some more tests and noticed that if I process the same job with the same ball nose bit it looks great..

example A - showing rough path and starting finishing path,

example B - showing finishing path only , we skipped the rough path, (great finish)

example C - showing finished rough path only.

any help would be greatly appreciated.

thanks,

Drew

- mrmfwilson

- Vectric Craftsman

- Posts: 239

- Joined: Thu May 31, 2012 6:49 pm

- Model of CNC Machine: Legacy Arty 36

- Location: Georgetown, TX

Re: Cut3d undesirable results

Can you post the Cut 3D file? It sounds like you are not setting up one of the paths with the correct bit. I say this because you mentioned that if you use the same ball nose bit it it comes out correct. If the roughing path is set up with a ball nose and you use an end mill you will not get the result expected.

Mike

Mike

- zeeway

- Vectric Wizard

- Posts: 3157

- Joined: Thu Feb 11, 2010 9:24 pm

- Model of CNC Machine: Self-built

- Location: SC, USA

Re: Cut3d undesirable results

Not likely a software problem. Are you putting in the tool you specified for the finish path? How are you resetting z zero for the second tool? Can you cut 2D shapes accurately?

Angie

Angie

- Mark

- Vectric Staff

- Posts: 1058

- Joined: Sat Aug 18, 2007 2:55 pm

- Model of CNC Machine: CNC Shark, ShopBot, Roland PNC3000

- Location: Alcester U.K.

- Contact:

Re: Cut3d undesirable results

Hello morph1,

I am afraid that I do not know too much about the "Toolpath" control software that

drives your machine, but I remember that some versions, required that you select

the job origin to the "CAD Origin" option. This option was located in the Layout section

on the Importing tab.

You may have a different version of the Toolpath control software than the one that I have seen in the

past, if so, perhaps a quick email to your machine tool supplier to ask if there is a similar

option for your version of the control software, might help.

I hope that this helps.

Cheers,

Mark.

I am afraid that I do not know too much about the "Toolpath" control software that

drives your machine, but I remember that some versions, required that you select

the job origin to the "CAD Origin" option. This option was located in the Layout section

on the Importing tab.

You may have a different version of the Toolpath control software than the one that I have seen in the

past, if so, perhaps a quick email to your machine tool supplier to ask if there is a similar

option for your version of the control software, might help.

I hope that this helps.

Cheers,

Mark.

Re: Cut3d undesirable results

thanks guys,

regarding my file , the origin with in cut3d is left bottom corner z is top...,

the tool path displays my file perfectly, the origin on the router table each path goes back the the origin as assigned for the first path,

the file preview looks exactly as expected, I mean if there was something wrong with my cut3d file setting wouldn't the cut3d render preview display it on the preview render...,

Material thickness 0.77" mdf ,

Machining Margins

Symmetrical 0.125" ON

Use Model Sillhouette ON

depth of model below surface 0.07"

cutting depth under surface is only 0.2",

Roughing Toolpath - Bit EndMill 0.25" dia. ,

pass depth 0.27", stepover 0.125"

toolpath parameters

Rapid Clearance gap 0.1"

Machining Allowance 0.04"

Strategy - 3D Raster Along Y

-------------------------------------

Finishing Toolpath - bit Ball Nose 0.25" dia.,

Pass Depth 0.3"

Step over 0.0225 @ 9%

toolpath parameters

Raster Angle 45 degrees

Rapid Clearance Gap 0.1

Output - generating 2 NC files,

each file sent and processed in the router table separately.

any ideas,

It looks like it offsets automatically in the toolpath router software...

maybe Mark is right, I will double check on import into toolpath..

thank you guys.

Can someone MSG me their e-mail address and I will send the file over ,

its nothing corporate , just a test file...

Cheers,

Drew

regarding my file , the origin with in cut3d is left bottom corner z is top...,

the tool path displays my file perfectly, the origin on the router table each path goes back the the origin as assigned for the first path,

the file preview looks exactly as expected, I mean if there was something wrong with my cut3d file setting wouldn't the cut3d render preview display it on the preview render...,

Material thickness 0.77" mdf ,

Machining Margins

Symmetrical 0.125" ON

Use Model Sillhouette ON

depth of model below surface 0.07"

cutting depth under surface is only 0.2",

Roughing Toolpath - Bit EndMill 0.25" dia. ,

pass depth 0.27", stepover 0.125"

toolpath parameters

Rapid Clearance gap 0.1"

Machining Allowance 0.04"

Strategy - 3D Raster Along Y

-------------------------------------

Finishing Toolpath - bit Ball Nose 0.25" dia.,

Pass Depth 0.3"

Step over 0.0225 @ 9%

toolpath parameters

Raster Angle 45 degrees

Rapid Clearance Gap 0.1

Output - generating 2 NC files,

each file sent and processed in the router table separately.

any ideas,

It looks like it offsets automatically in the toolpath router software...

maybe Mark is right, I will double check on import into toolpath..

thank you guys.

Can someone MSG me their e-mail address and I will send the file over ,

its nothing corporate , just a test file...

Cheers,

Drew

- mrmfwilson

- Vectric Craftsman

- Posts: 239

- Joined: Thu May 31, 2012 6:49 pm

- Model of CNC Machine: Legacy Arty 36

- Location: Georgetown, TX

Re: Cut3d undesirable results

Not that it should make a big difference but those are aggressive cutting depths. I generally don't go larger than the diameter of the bit for a depth of cut. Most of the time I use half of the diameter. Those are general rules for hand routing. Some folks recommend not more than 1/8 of an inch at a time no matter what size bit you are using for hand routing. Also I generally stay away from the 45* routing. If your machine is slightly off or out of adjustment it seems to accentuate the misalignment. I guess you are not using Mach for the routing software? If the file is not too large you can just attach it to a post.

Re: Cut3d undesirable results

Thanks for the time to examine my data,mrmfwilson wrote:Not that it should make a big difference but those are aggressive cutting depths. I generally don't go larger than the diameter of the bit for a depth of cut. Most of the time I use half of the diameter. Those are general rules for hand routing. Some folks recommend not more than 1/8 of an inch at a time no matter what size bit you are using for hand routing. Also I generally stay away from the 45* routing. If your machine is slightly off or out of adjustment it seems to accentuate the misalignment. I guess you are not using Mach for the routing software? If the file is not too large you can just attach it to a post.

I am using toolpath for routing, I ran a bunch of tests and still getting same results...,

could anyone check the file by itself and let me know if that looks ok besides the aggressive settings that Mrmfwilson has mentioned...

I was wondering about the bits , the secondary cut must be fine as there is onle one king of ball nose bit.., now the first rough cut,

maybe there is a problem with the bit..., what type of bit is an end mill bit?, what the operator used is Solid Carbide Single Flute same diameter as specified in Cut3D...,

http://bytesbox.com/!/U85ZWOuTpiAq5Tk/

thank you all,

Drew

-

robjeffking

- Posts: 22

- Joined: Fri Mar 22, 2013 4:17 am

- Model of CNC Machine: Zenbot 4848

Re: Cut3d undesirable results

What about your collet and runout.